Cutting-edge DTF Printing Solutions: Boost Your Clothing with Direct-to-Film Technology

Wiki Article

The Future of Fashion: Discovering DTF Printing Innovation in the Textile Sector

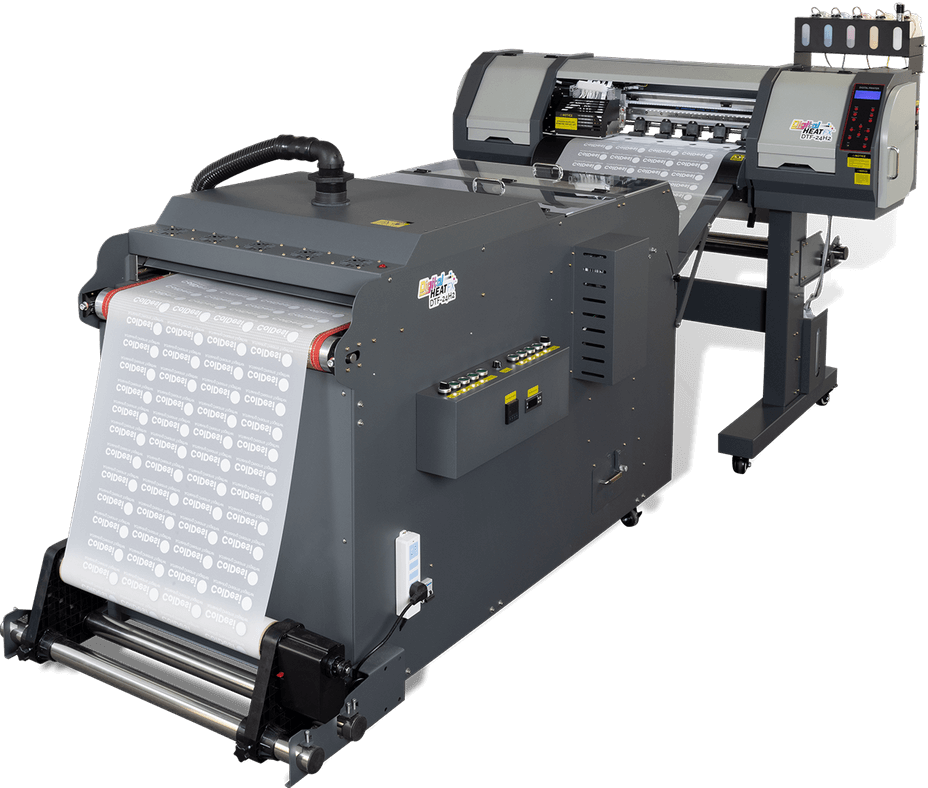

Among these developments, Direct to Film (DTF) printing modern technology has actually emerged as an encouraging challenger, providing distinct capacities and possibilities for designers and producers alike. This cutting-edge printing method has actually sparked passion due to its prospective to revolutionize traditional textile printing processes.Advancement of Textile Printing

From the old human beings utilizing strategies like block printing to the electronic revolution of today, textile printing has actually continuously pushed borders. As the craft spread to other parts of the world, brand-new methods such as display printing and roller printing emerged during the Industrial Revolution, reinventing the fabric industry.

The intro of digital fabric printing in the late 20th century marked a considerable change towards more flexible and lasting printing techniques. The development of textile printing showcases an abundant history of creativity, ingenuity, and technological progression in the world of style and layout.

Advantages of DTF Technology

With the evolution of textile printing techniques from ancient methods like block printing to modern innovations such as electronic printing, the introduction of Direct-to-Fabric (DTF) innovation has actually considerably improved the performance and sustainability of textile printing procedures. Among the primary advantages of DTF technology is its capacity to straight print styles onto textile without the need for transfer papers, which minimizes waste and simplifies the manufacturing process. Additionally, DTF printing enables for higher color vibrancy and detail precision contrasted to standard methods, allowing fabric suppliers to produce high-grade and intricate styles effortlessly.Additionally, DTF innovation is recognized for its adaptability, as it can be utilized on various kinds of fabrics, consisting of all-natural fibers like silk, cotton, and wool, in addition to artificial materials such as polyester and nylon (DTF Printing). This flexibility opens up a wide variety of opportunities for designers and producers to trying out various appearances and products, resulting in more one-of-a-kind and ingenious products in the fashion business. Generally, the execution of DTF modern technology represents a considerable innovation in fabric printing, using numerous advantages that add to the future sustainability and creative thinking of the market

Sustainability in vogue Manufacturing

Stressing green practices is extremely important in contemporary style manufacturing, lining up with the expanding customer need for lasting products. In recent times, the style industry has actually faced enhancing analysis due to its significant environmental influence, consisting of extreme water use, chemical air pollution, and fabric waste. As a reaction, lots of fashion brand names are currently including lasting methods right into their manufacturing processes to reduce harm to the environment.Sustainability in fashion production encompasses numerous elements, such as making use of natural and recycled materials, reducing energy usage, executing moral labor techniques, and advertising transparency throughout the supply chain. Furthermore, developments in innovation, like DTF printing, offer opportunities to additionally enhance sustainability in textile production. This technology enables exact printing on materials, decreasing ink wastage and water use compared to typical printing methods.

Layout Liberty and Personalization

In addition, DTF printing helps with personalization on a range formerly unattainable, allowing for personalized garments and one-of-a-kind pieces customized to individual choices. Customers can now proactively take part in the layout procedure, creating garments that mirror their style and character. This personalization not only improves the customer experience however additionally advertises a sense of exclusivity and originality in a market filled with mass-produced garments. Generally, DTF printing technology reinvents the style go to these guys landscape in the textile sector, using unlimited possibilities for creative expression and customized style.

Effect On Supply Chain & Market Trends

DTF printing technology in the fabric sector is reshaping supply chain characteristics and influencing market patterns with its performance and modification capabilities. By allowing on-demand printing and eliminating the requirement for huge supplies, DTF innovation this page simplifies the supply chain procedure.

Additionally, the modification potential of DTF printing innovation is reinventing the marketplace patterns in the textile industry. Customers increasingly look for special and individualized products, and DTF enables brands to offer custom layouts cost-effectively. This customization ability not only boosts customer satisfaction yet likewise opens brand-new possibilities for organizations to provide to particular niche markets and separate themselves from competitors. Therefore, DTF modern technology is driving a change towards even more innovative and customer-centric approaches within the textile market, shaping the future of style.

Conclusion

Finally, DTF printing innovation is revolutionizing the fabric sector by using countless advantages such as design personalization, freedom, and sustainability. This innovative technology is reshaping the future of style production, impacting supply chains, and driving market trends in the direction of extra reliable and green methods. As the sector proceeds to develop, DTF printing will play a crucial function in forming the way fabrics are generated and eaten in the years to find.From the ancient human beings utilizing strategies like block printing to the digital change of today, fabric printing has actually consistently pressed boundaries. As the craft spread browse around this site to various other components of the world, brand-new techniques such as display printing and roller printing emerged throughout the Industrial Transformation, revolutionizing the textile sector.

The introduction of electronic textile printing in the late 20th century marked a significant change in the direction of more lasting and flexible printing methods.With the advancement of fabric printing strategies from ancient techniques like block printing to modern innovations such as digital printing, the intro of Direct-to-Fabric (DTF) technology has substantially enhanced the effectiveness and sustainability of textile printing processes (DTF Printing).In action to the critical change towards sustainability in style production, the adoption of cutting-edge technologies like DTF printing not just addresses environmental worries however additionally opens up methods for exceptional style flexibility and modification in the textile industry

Report this wiki page